Minimise repetition and waste

Established in the early days of computers in manufacturing, CES has invented and developed software to facilitate engineering manufacture with proven technology that delivers quick results.

Time is Money

Use Cost Engineering to accurately calculate the time and cost of manufacturing, delivering reliable estimates for better profitability.

Proven Technology

Created by engineers for engineers with reliable technology, improved over many years, to make pre-production work quick and simple.

Quick Results

Our software products are fast and reliable to save you time and effort, with excellent support and extensive documentation.

Our software solutions

Two powerful software products designed to optimise your manufacturing operations and maximise efficiency.

Cost Engineering

Advanced manufacturing cost calculation software with CO2 emissions monitoring

ShapeNest

Advanced profile cutting software with semi automatic nesting for CNC machines

Powerful features for modern manufacturing

Both products deliver cutting-edge capabilities designed to streamline your manufacturing processes and improve operational efficiency.

Cost Engineering Features

Accurate Cost Calculation

Win more bids or cut costs with precision quoting. Our intelligent algorithms factor in every manufacturing variable to deliver spot-on estimates that protect your margins and beat the competition.

CO2 Emissions Monitoring

Turn sustainability into competitive advantage. Real-time carbon tracking helps you meet environmental targets, win eco-conscious contracts, and demonstrate your commitment to a greener future.

Multi-user Collaboration

Break down silos, boost productivity. Your entire team—from shop floor to C-suite—works from the same real-time data, ensuring everyone makes decisions based on the latest information.

ShapeNest Features

Material Optimisation

Slash material costs by up to 30%. Our smart nesting algorithms squeeze every possible part from your plates, turning waste into profit with intuitive drag-and-drop placement.

Multiple Cutting Methods

One software, endless possibilities. Whether you're running plasma, laser, waterjet, or oxy-fuel systems, ShapeNest speaks your machine's language with native ESSI and G-code support.

CAD Integration

From design to cut in seconds. Import DXF files directly or sketch parts on the fly with built-in drawing tools—no more switching between programs or manual data entry.

Industry applications

Our software solutions deliver precision and efficiency across multiple manufacturing sectors.

Precision Engineering

Calculate manufacturing costs accurately for complex precision parts and optimise cutting operations.

Aerospace & Defense

Meet strict quality standards and documentation requirements while maintaining precise cost control.

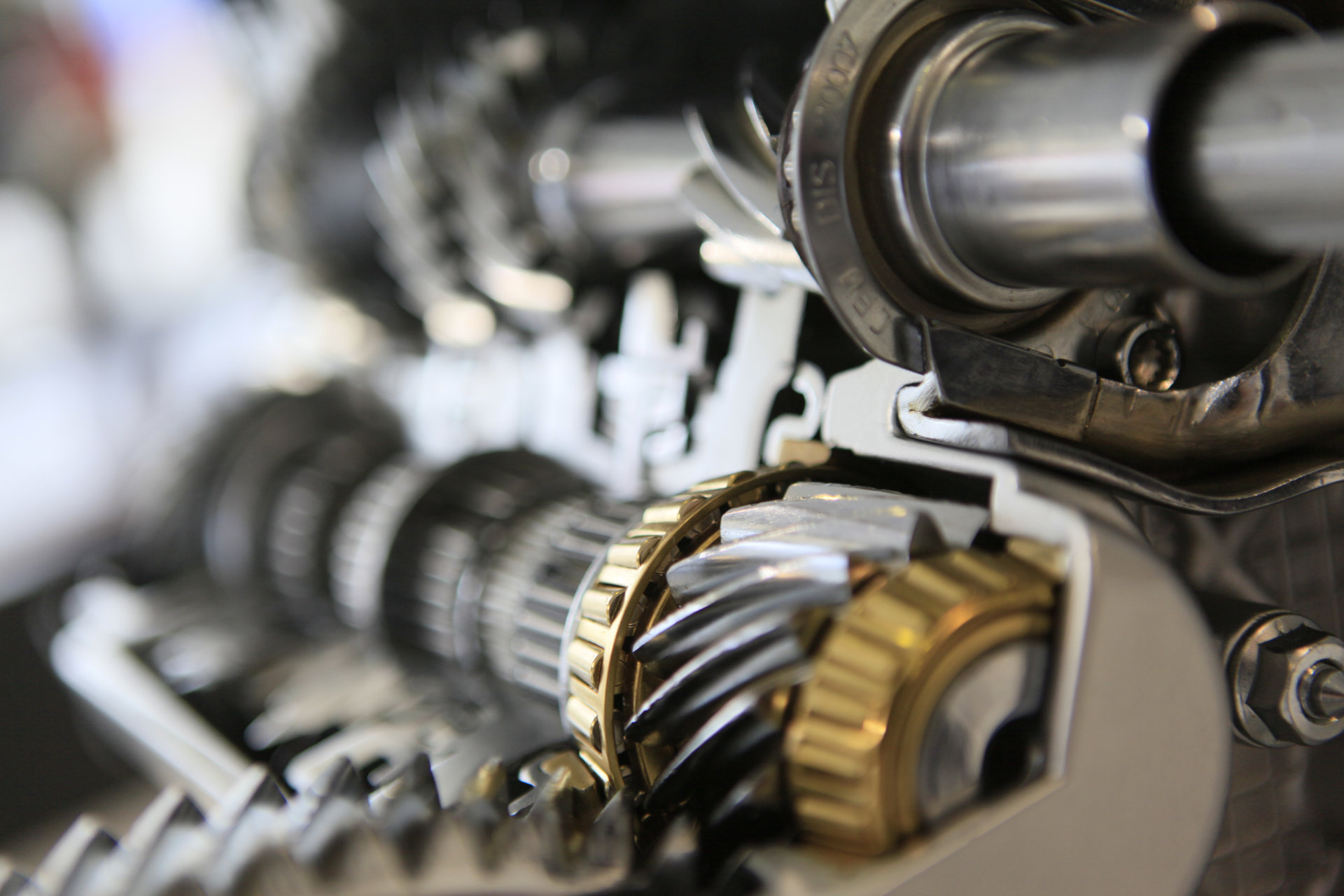

Automotive

Optimise production costs and resource allocation for high-volume manufacturing environments.

Metal Fabrication

Maximise material usage and reduce waste with easy to maniplulate nesting and detailed nest analysis.

Technology to fit your profile

Monthly Licensing

Make a one-month investment and see what benefits it brings to your manufacturing operations.

Excellent Support

Extensive documentation and post-sale support to get the most from our products.

Maximising your time and materials

Our close cooperation with you ensures you get the most value from our products and your investment in both resources of time and material.

Ready to transform your manufacturing operations?

Contact us today to learn more about our software solutions and how they can help you maximise efficiency, minimise waste, and improve profitability.