Powerful features

Cost Engineering combines advanced manufacturing cost calculation with environmental monitoring to help you deliver on time, improve competitiveness and increase profitability.

Accurate Cost Calculation

Precisely calculate manufacturing time and costs with advanced algorithms

CO2 Emissions Monitoring

Track and report your environmental impact with detailed emissions data

Multi-user Collaboration

Centralised database for team access across departments or locations

Real-time Estimating

Create detailed manufacturing estimates directly from CAD inputs

Resource Planning

Optimise production schedules and resource allocation for maximum efficiency

Historical Analysis

Compare estimated vs actual manufacturing data for continuous improvement

Comprehensive cost management

Cost Engineering provides the tools you need to manage every aspect of manufacturing costs, from initial estimation to performance analysis.

Estimation & bidding

Create detailed estimates based on historical data and industry standards. Calculate quotation, cost price, bid price, should cost, and will cost with confidence.

Apply customer-specific markup and discount rates, with tooling costs that can be amortised over order quantities or retained as fixed charges.

Real-time costing

Calculate manufacturing time and costs in real-time with parameterised part definitions that quickly update when specifications change.

Use learning curves for each manufacturing resource to account for time reduction through repetition, and apply cost breaks for bought-out items and subcontract operations.

Comprehensive reporting

Generate predefined reports for manufacturing processes, estimated vs. actual times, bid prices with quantity breaks, and assembly lists.

Create user-defined reports for shop floor documentation, purchase orders, MRP/ERP export, internal workflow, and customer quotations with built-in email.

Industry applications

Cost Engineering software delivers precision and efficiency across multiple manufacturing sectors.

Precision engineering

Calculate manufacturing costs accurately for complex precision parts, improving quote accuracy and profit margins.

Aerospace & defense

Meet strict quality standards and documentation requirements while maintaining precise cost control.

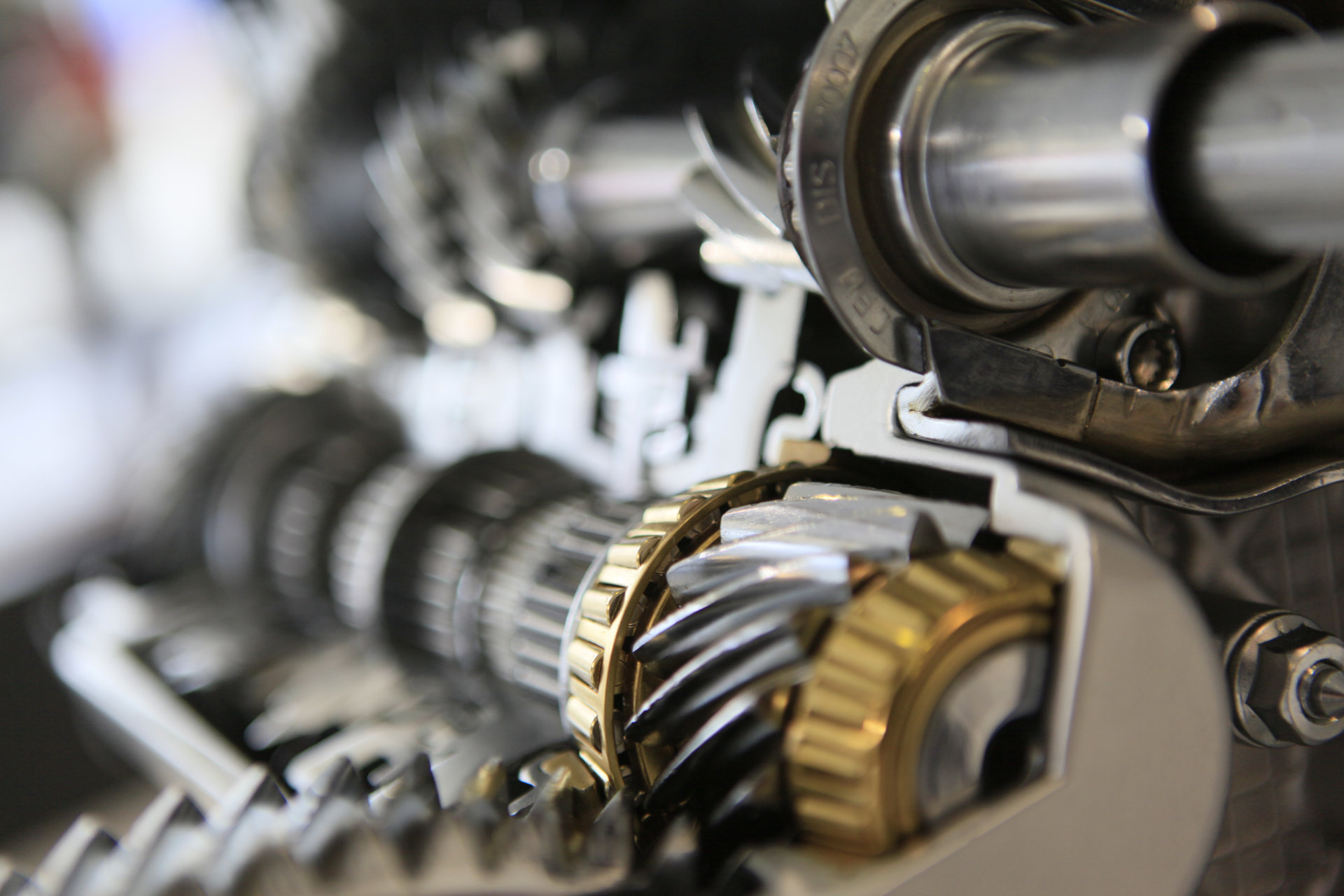

Automotive

Optimise production costs and resource allocation for high-volume manufacturing environments.

Sub-contract machining

Quickly assess time and cost for new designs or repeat orders, prepare routing and integrate with order processing.

Shipbuilding

Manage complex projects with size, complexity, plant and capacity calculations stored in the central database.

Electronics

Time and cost manual or robotic placement and processes with precision for high-volume production.

Heavy equipment

Custom fabrication or machining with accurate quotes for one-off projects with specific designs and materials.

Toolroom & fastenings

Internal costings, lead time predictions, and assessment of manufacturing process changes for bespoke or standard ranges.

Also ideal for: One-off projects (both large and small scale) and Large batch production where precise cycle time calculations ensure accuracy across high volumes.

Technical capabilities

Cost Engineering software delivers the advanced features that manufacturing professionals demand.

Cost calculation tools

- Advanced time calculation algorithms for manufacturing operations

- Material database with speeds, feeds, power factors grouped by operation type and material specifications

- Parameterised part definition for quick family-of-parts calculations

- Associated documents system with drawings linked to parts and operations

- Advanced part/assembly management with methods, revisions, and operations

Reporting features

- Multi-user centralised database with administrator permissions

- Data integrity with automatic saving and validation of entries

- CO2 emissions monitoring and environmental impact analysis

- Customisable reporting templates with shop floor documentation and bar codes

- Export/import capability for sharing database entries between user groups

Maximise your manufacturing efficiency

Improved accuracy

Deliver more reliable cost estimates with customer-specific markup and discount rates, learning curves, and built-in material specification data

Enhanced profitability

Identify cost-saving opportunities and optimise pricing strategies with detailed cost breakdowns

Environmental compliance

Meet sustainability goals and regulatory requirements with integrated CO2 emissions monitoring and reporting

Streamlined operations

Collaborate efficiently with multi-user access, centralised database, and integrated document management with drawings linked to parts and operations

Team collaboration & data management

Cost Engineering provides enterprise-grade features for team collaboration, data integrity, and efficient workflow management.

Multi-user collaboration

Centralised database with multi-user access enables teams to collaborate across departments or worldwide. Administrator and user permission controls ensure data security.

Context-sensitive help and comprehensive user documentation facilitates staff training and onboarding.

Data integrity & security

Administrator users control static data like plant hourly rates. All entries are saved automatically, with keyboard input validated immediately against expected values.

Data integrity prevents deletion of data used elsewhere. Backup options per session or on demand, with multi-database support for experimentation.

Shared data management

Export and import database entries for tasks, machines, tools, and static data to enable data exchange between user groups.

Automatic updates from our Licence Portal keep your software current with the latest features and improvements.

Get started with no up-front costs

Cost Engineering comes complete with sample data to help you get started immediately, with easy customisation to match your business.

Complete sample data included

Start immediately with pre-loaded sample data including machines, tools, materials, tasks, and example parts. Everything is customisable - just update the hourly rates and efficiency settings to match your operation.

Plant details including names, hourly rates, and efficiency ratios are easily customised to match your specific requirements.

Automatic updates & recalculation

When specifications change, plant overheads adjust, stock materials update, or order quantities vary, the system automatically recalculates all times and costs.

Unlike spreadsheets that require manual updates, Cost Engineering automatically recalculates everything. Your quotes are always accurate, using the latest costs and rates.

Simple, transparent pricing

Get started with Cost Engineering software with our flexible licensing options.

First license

Full-featured Cost Engineering license

Second license

Add another workstation

Additional licenses

For three or more workstations

Calculate your license cost

Frequently asked questions

Find answers to common questions about Cost Engineering software for manufacturing cost calculation and emissions monitoring.

Ready to optimise your manufacturing costs?

Contact us today to discover how Cost Engineering can transform your manufacturing operations. Get accurate quotes, win more work, and improve your margins.